Presentation

There is no truck owner who has not asked himself at least once this question: what happens if you put regular gas in a diesel truck? The answer is tragic. Gasoline and diesel are two fuels that are completely different in their chemical properties and combustion demands. In contrast to gasoline engines that utilize spark ignition, diesel engines use compression ignition. Mixing them can lead to not only reduced efficiency it can also cause instant performance problems and long-term diesel engine damage. With the help of this guide, you will be able to understand the risks of gasoline contamination, the importance of proper diesel engine care, and the need for warranty adherence, compared to costly fuel system repair caused by misfueling.

Immediate Effects of Gasoline in a Diesel Engine

Engine Misfires and Stalling

One of the initial misfueling symptoms you may experience is engine misfire. Gasoline is not a fuel for diesel engines, and gasoline improperly mixes with diesel, forcing it to burn incorrectly and leading to ragged idle symptoms, typical idle instability, and sometimes even the risk of engine knock. Often, the truck may go into limp mode or simply experience engine stalling, leaving the driver stranded. This fuel grade incompatibility also explains cold start problems and unstable combustion when there are high enough concentrations of gasoline in the mixture.

Fuel System Contamination

Gasoline is a solvent that strips lubrication away from critical diesel engine components. Once it circulates, it causes fuel line contamination and begins the process of fuel system corrosion. Diesel fuel injectors and pumps rely on lubrication to prevent pump failure risk and injector seal damage. Gasoline reduces this protective layer, resulting in moisture in fuel l rail fouling, fuel system problems, and even engine shutdown risk. In many cases, even a small amount of gasoline can increase the gasoline dilution risk, making an emergency fuel purge or a full fuel drain procedure necessary.

Long-Term Consequences

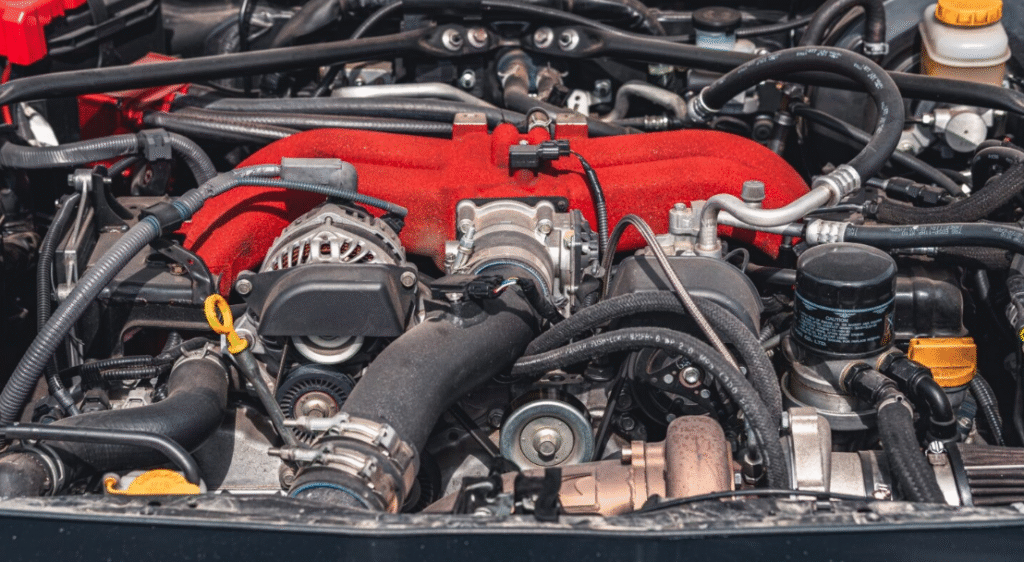

Damage to Fuel Injectors and Pumps

If the contaminated mix remains in use, fuel injector damage and diesel fuel pump issues become inevitable. Clogging may occur due to cleanup delays, while seals deteriorate because of lost lubrication. The result is injector clogging, pump failure risk, and costly fuel system flushing combined with fuel filter replacement. Often, mechanics must also deal with corrosion in the corrosion in fuel pump, which complicates fuel system servicing and diesel engine troubleshooting.

Putting Gasoline In A Diesel Car – What Happens?

Potential Engine Damage

The most severe risk is permanent diesel engine damage. Gasoline disrupts the combustion cycle, creating oil dilution risk, engine knock risk, and long term engine wear. In some cases, this results in exhaust catalyst damage or the need for major post misfueling repair. Manufacturers may also deny coverage due to warranty impact risk caused by misfueling. Without timely fuel system inspection, the diesel engine issues faces premature deterioration and serious diesel engine performance issues.

Steps to Take if Misfueling Occurs

Do Not Start the Engine

If you accidentally filled the tank with gasoline, do not start the engine. Turning the key will circulate the contaminated fuel into vital diesel engine components, increasing the chance of fuel system damage, engine shutdown risk, and widespread fuel tank contamination. Keeping the truck off makes fuel system cleaning and repairs much simpler.

Contact a Professional Mechanic

Always contact a professional specializing in diesel engine repair and fuel system diagnostics. They can evaluate the level of fuel system contamination, carry out diesel engine troubleshooting, and recommend a safe fuel system cleaning plan. Their expertise ensures proper fuel system inspection delay avoidance and reduces the risk of overlooking hidden fuel system problems.

Draining and Flushing the Fuel System

A standard recovery procedure involves draining the tank, performing an emergency fuel purge, and completing a full fuel system flush. Mechanics then conduct fuel filter replacement and check for fuel system seals damage or injector seal damage. Depending on contamination cleanup severity, additional fuel system maintenance or fuel system servicing may be required. The fuel system flush cost can range from hundreds to thousands, depending on discovered engine performance issues such as idle instability, engine limp mode, or cold start problems.

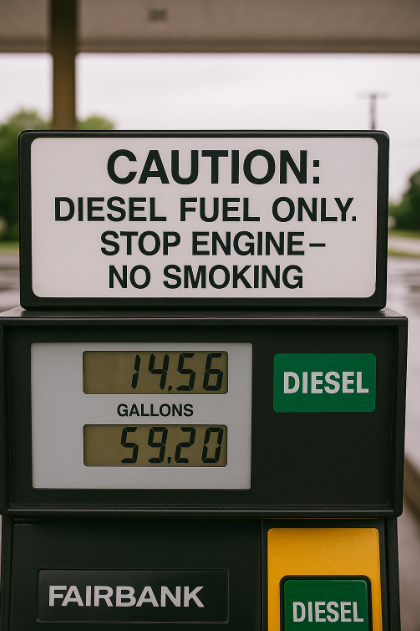

Preventative Measures to Avoid Misfueling

Labeling and Color-Coding Fuel Caps

A simple but effective misfueling prevention method is labeling. Bright stickers or color-coded fuel caps reduce confusion at the pump. This practice is especially helpful in fleets focused on diesel truck maintenance, fuel system maintenance, and avoiding fuel system damage.

Educating Drivers on Fuel Types

Training programs for drivers help them understand diesel fuel properties, fuel grade incompatibility, and the dangers of gasoline contamination. Regular misfueling awareness training ensures drivers can recognize engine performance issues early and take action to prevent further fuel system damage. Such staff education lowers long-term diesel engine maintenance costs and prevents unnecessary engine warranty disputes.

Installing Misfueling Prevention Devices

Many fleets install misfueling prevention devices designed to block smaller gasoline nozzles from entering diesel filler necks. These devices prevent fuel system damage, reduce post misfueling repair incidents, and help extend diesel engine care intervals. For long-haul trucking, they are especially effective at minimizing mistakes during quick refueling stops.

Conclusion

The vehicle’s and of the driver tasks are not the same here. The statement proposes a situation in which the common car driver may rather put the gasoline into the diesel truck than to the car. When a common car driver mistakenly puts gasoline in diesel engine truck, he is experiencing a very serious problem. The immediate results of this act, i.e. the incidents such as engine misfire, engine stalling, and fuel system contamination which are really quite common are the immediate effects who in time lead to fuel injector damage, the diesel fuel pump failure, and even the deserting the engine of the diesel truck. The best method is the following: if you misfuel, do not start the truck, call a professional to service the fuel system and then flush it out the right way. Owning with the help of such strategies as color-coded fuel caps, driver training, and misfueling prevention devices which have part only, owners can stop stretching their pockets to repair the fuel rail fouling system, help keep their engine warranty, and also help keep their diesel engine at the top of their performance.