Introduction to Dump Truck Capacities

Quite clearly, the vital aspect that a construction equipment operator should note concerning the typical dump truck is whether it can fit the materials in the dump truck bed. Many beginners start by asking a simple but crucial question: how many yards in a dump truck? This almost basic inquiry promotes the need for structural engineering planning, hauling materials, and efficiency in construction equipment works. Low weights also make it easier for trucks to navigate tighter spaces compared to larger dump truck sizes which usually have lower maximum payloads.

Being aware of the dump truck capacity is a crucial thing to deal with as it also helps you with these two main components, the volume capacity (by measuring the volume in cubic yards) and weight limit (set by legal and mechanical rules). For instance, this knowledge includes the volume of the dump bed, dimensions of the truck bed, the material weight, and the weight of the payload, hence, the ability to manage the site loads without delays, fines, or other unexpected costs.

This guide will go through some common dump truck types, what affects their loading capacity, and how to do accurate load estimation and volume estimation for your construction equipment or landscaping jobs.

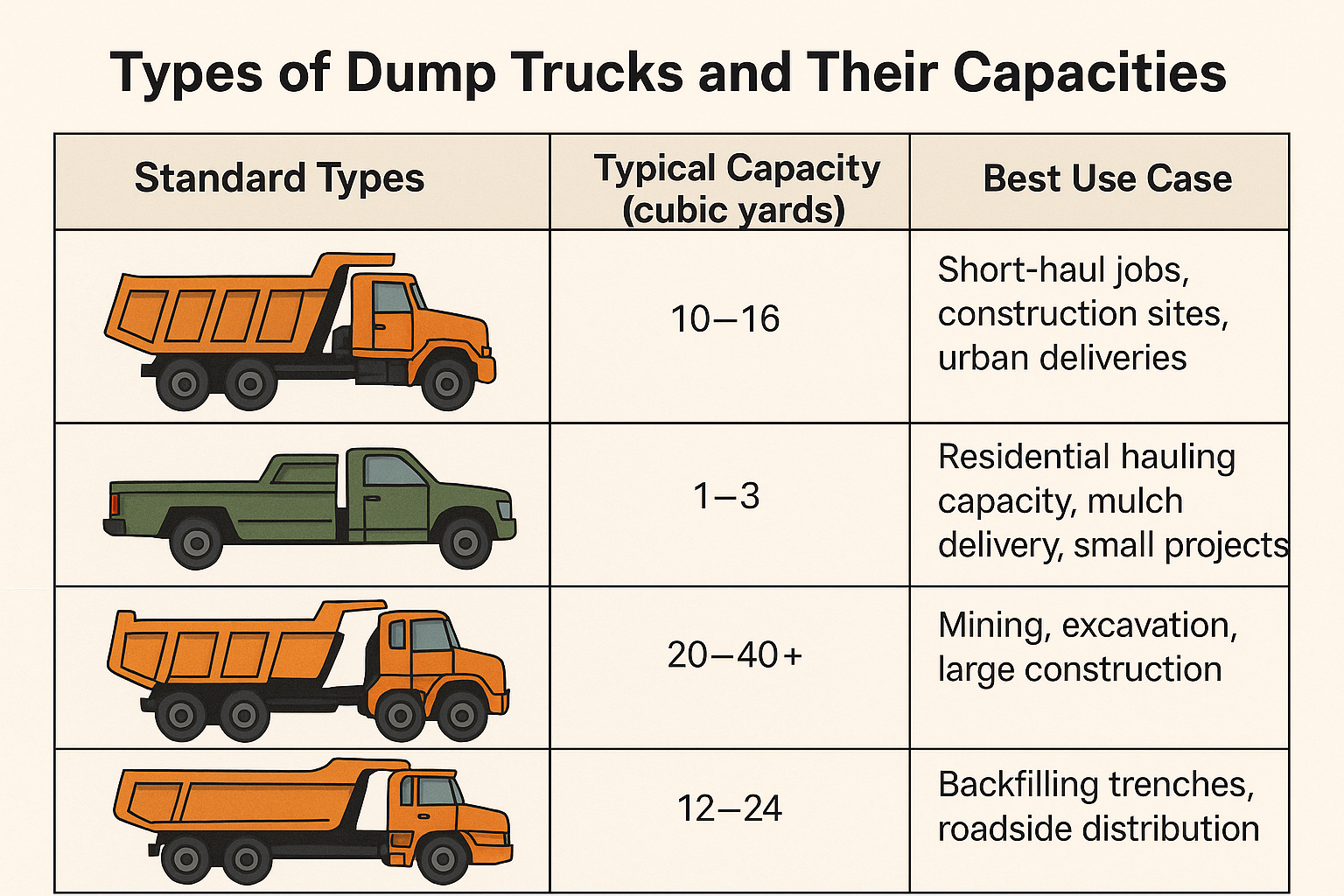

Types of Dump Trucks and Their Capacities

| Dump Truck Types | Typical Capacity (cubic yards) | Best Use Case | Efficiency Notes |

| Standard Dump Truck | 10–16 | Short-haul jobs, construction sites, urban deliveries | Compact and manoeuvrable but lower payload compared to larger models |

| Pickup-Mounted Dump | 1–3 | Residential hauling capacity, mulch delivery, small projects | Ideal for small jobs, multiple trips manageable with good load scheduling |

| Articulated Dump Truck | 20–40+ | Mining, excavation, large construction | High payload, works well on rough terrain and off road dump conditions |

| Side Dump Truck | 12–24 | Backfilling trenches, roadside distribution | Faster unloading, requires careful safety guidelines to prevent spillage |

Standard Dump Trucks

The typical recognizable sign of standard dump trucks is that they consist of a truck chassis mounted with a dump bed of hydraulic lift capability. They are generally used to carry construction materials such as dirt, sand, or gravel.

Capacity: Usually from 10 to 16 cubic yards depending on the bed dimensions and brand.

Use Case: The go-to for short-haul jobs, construction sites, and urban deliveries.

Efficiency: Their compact build allows them to navigate tighter spaces, however, they have lower maximum payload compared to larger models.

Pickup-Mounted Dump Trucks

In case of minor optimization issues, pickup-mounted dump trucks are very flexible for smaller landscaping projects or light-duty material hauling. These vehicles are a combination of pickup trucks and modified dump beds.

Capacity: Approximately 1–3 cubic yards of material.

Use Case: Primarily, the best fit for residential hauling services, mulch delivery, or small construction equipment jobs.

Efficiency: Excellent for payload planning in small jobs where numerous trips are workable and careful load scheduling keeps operations efficient.

Articulated Dump Trucks

The cab and bed joint pivot allows for better maneuverability on uneven surfaces. Articulated dump trucks are heavy-duty vehicles designed for rough terrain, mining operations, and big construction projects.

Capacity: 20–40+ cubic yards.

Use Case: Moving excavation materials, heavily loaded rock cargo, or large amounts of construction debris from one site to another.

Efficiency: High payload capacity, but requires more ground clearing and careful transport weight management.

Side Dump Trucks

The side dump trucks, which are quite different from the traditional models, are the directional-dumping trucks. A side dump truck tips the material sideways instead of tipping it at the rear position.

Capacity: Approximately 12–24 cubic yards depending on the design.

Use Case: The most effective for distributing loads over the roadside, backfilling trenches, and constructing linear projects.

Efficiency: The side unloading is quicker, however, it needs strict safety guidelines to prevent spillage.

Factors Affecting Dump Truck Capacities

Material Density

Weight per cubic yard differs according to the materials, and the main density is the weight. Some specimens are:

- Soil density: almost 2000 lbs for each cubic yard

- Gravel density: almost 2800 lbs for each cubic yard

- Rock density: around 3000+ lbs for each cubic yard

- Dirt density: altered frequently with regards to compaction and moisture

A good rule of thumb would be that if the truck’s rating is based on the weight of the truck, using denser materials would bring an extra load that might require the truck to go over the rated weight. Knowing the mass per cubic yard ensures operators can match density to the truck’s rated bed capacity.

Even if you know how many yards in a dump truck, the true usable load depends heavily on density and material weight. Dense materials like gravel or rock may quickly exceed safe weight limits despite fitting in terms of volume.

Weight vs. Volume Limits

A truck has a maximum payload determined by its design and the manufacturer’s specification. Payload is limited not only by weight but also by space. For example, a standard dump truck might hold 12 cubic yards of ballast but only 8 cubic yards of gravel because of the weight difference.

Local Regulations

Local regulation limits increase the issue of truck weight rating, axle loads, and tipping height, prioritizing safety. Overloading can result in fines, poor haul optimization, and added wear on the vehicle. Following regulations is essential in project planning and load calculations.

Calculating Dump Truck Loads for Your Project

Estimating Number of Loads Needed

- Measure Truck Bed Dimensions: Length × width × height = bed volume in cubic feet.

- Convert to Cubic Yards: Divide cubic feet by 27.

- Adjust for Material Density: Multiply volume capacity by the weight per yard for the specific material.

- Compare to Payload Capacity: Ensure your calculation does not exceed the truck’s maximum payload or weight restrictions.

Example: A dump bed volume of 300 cubic feet equals ~11 cubic yards. If hauling gravel ~2,800 lbs/yard, the load weighs ~30,800 lbs. If the truck limits payload to 26,000 lbs, the load must be reduced to ~9 cubic yards.

This process shows how volume estimation, material weight, and load calculations work together for safe operation.

Practical Considerations

- Compacted volume: Wet or compressed materials take up less space but weigh more.

- Haul distance: Longer hauls increase fuel costs and reduce effective haul rate.

- Load distribution: Uneven loading raises tipping risk.

- Project efficiency: Splitting loads may better match site staging needs.

- Haul optimization: Proper sequencing and load scheduling makes material transport more efficient.

Conclusion

Realizing the enormous dimensions of dump trucks and the real cargo they can transport gives contractors, landscapers, and project managers the ability to exactly choose what is required. Inquiring about the number of yards in a dump truck is just a prototype, the value sets in the true understanding of the balance of volume estimation, material density, material weight, and regulation limits in conjunction with the site requirements.

Following appropriate load calculations, remaining within transport weight limits, and adequate payload planning, projects gain the benefit of more efficient material flow, reduced risks, and on-time completion. Whether you use a pickup-mounted dump truck in residential jobs or an articulated off road dump truck for major earthmoving tasks, mastering the interrelationship between cubic yards, mass per cubic yard, and truck bed capacity is the foundation of professional planning for hauling materials.